Commonly used material for stamping hardware fittings

Hardware is not a new word to everyone, the meaning of the word is five metals. The word "hardware" first appeared in the book "wu yue spring and autumn", referring to gold, silver, copper, iron, tin. Due to the vigorous development of modern technology, metal materials used by the metal industry are far more than these, zinc, aluminum, manganese and other large applications, a variety of alloys are emerging in endlessly, the development of metal stamping industry is more rapid.

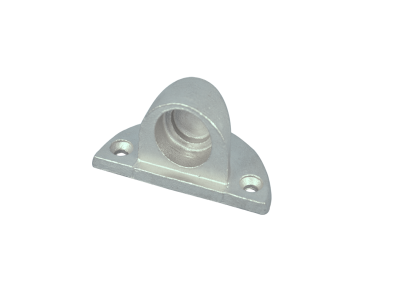

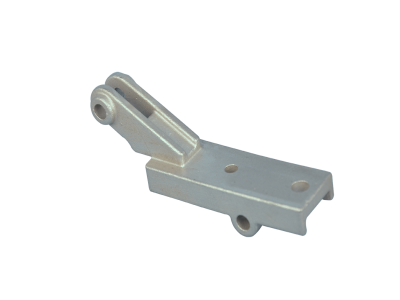

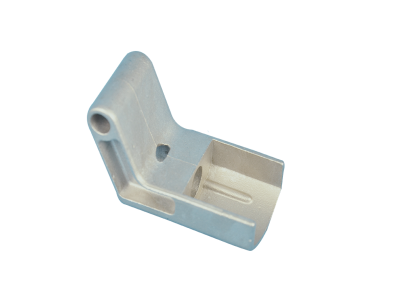

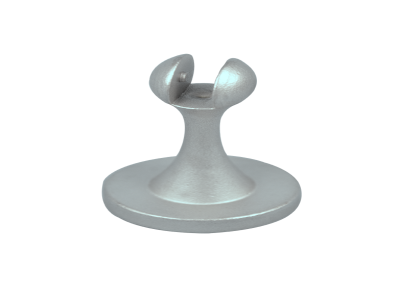

We have a lot of products in life have hardware stamping parts, such as part of the car body parts, computer chassis shell, some of the furniture accessories and so on. Carbon steel should be the most widely used. Because of its low price and excellent performance, carbon steel plays an important role in the hardware industry.

Generally speaking, there are different grades of carbon steel, the most commonly used grade is Q235, which is also divided into four grades A, B, C and D. I won't go into details here. Due to good plasticity and low price, Q235 carbon steel is used for metal stamping parts with low performance requirements. There are many kinds of carbon steel, such as hot - rolled and cold - rolled, galvanized and tinned, and so on. Some high quality carbon steel such as 45# steel, greater hardness, metal stamping needs to consider the tonnage of the machine tool and whether the product bending and bending degree. If the bending is too large, so that the workpiece is damaged, then you need to consider whether to use other materials instead.

Carbon steel's brother, stainless steel, is also one of the most widely used materials in the industry. Stainless steel contains a variety of metal elements, which greatly enhances the rust resistance and is widely used. We often say 201,301,304,316 are relatively common stainless steel brands.